Status quo

At present, the blast furnace coal injection is an important technology of universally adopted in international field, but measuring concentration in front of the pulverized coal combustion in industrial furnace, mostly using conventional pulverized coal thermal instrumentation for the online measurement, in order to change the consumption of coal, or use the electronic said of industrial furnace combustion of pulverized coal by supporting tundish, coal injection can measure. Showed in the practice, practical, the former need to summary and analysis of various parameters, conversion, big workload and low accuracy, instantaneous flow variation, which is difficult to response cannot be achieved in furnace combustion automatic control, directly affects the working condition of the stability and boiler combustion efficiency.

Over the past twenty years, with the huge increase of energy consumption and the crisis of oil reserves in the industry to produce, gradually transite from jet fuel to the injection powder technology in the blast furnace ironmaking. To the blast furnace coal injection in the purpose is to reduce the coke rate, furnace temperature control. Evenly in order to make the pulverized coal combustion in blast furnace, the best wind coal ratio control, need to know the amount of coal injection gun. So the coal injection flow detection is obtained the research and development.

Solution

DLT - CPFM - X pulverized coal concentration on-line monitoring system, uses the concentration of capacitive sensor and speed through the method of time difference capacitance sensors and pulverized coal mass flow cell, can accurate online continuous measurement of blast furnace coal injection main concentration and velocity of each branch. Is fills the blank of the domestic and international advanced technology level of gas-solid two phase flow online monitoring device. The device has extremely independence road and reasonable way on the design concept, it has strong resistance not only in the blast furnace coal injection system, but also in wind system in thermal power plant boiler, dry ash handling system and pneumatic conveying system. It can be applied to various forms of pulverized coal injection system, and installed simply.

Characteristics

1) It is suitable for the main and branch pipe of pulverized coal concentration, velocity and mass flow rate measurement.

2) With the influence of the pressurized, high measurement precision.

3) With no pressure loss to pipeline system to be measured.

4) Installation and maintenance is convenient.

Main function

1) Main branch pipe on-line monitoring and display of pulverized coal concentration, velocity and flow rate.

2) Blocking pipe diagnosis, prompt to adjust in a duct wall tube trend.

3) Powder fault diagnosis, prompt to adjust when broken powder for powder machine.

4) Show information pulverized coal concentration in numerical, bar charts, trend charts and so on.

5) It can be used in the blast furnace combustion adjustment and performance test.

Performance indicators

1 Main pipe:

1) Temperature: - 30 ~ + 70℃

2) Medium pressure: < 1.6 MPa

3) Pulverized coal concentration: 0 ~ 20 Kg (solid)/Kg (gas)

4) Measuring range: 0 ~ 100 t/h

5) Medium speed: 7 ~ 25 m/s

6) Accuracy: plus or minus 5%

7) power supply: AC220V / 1 kva

2 Branch pipe:

1) Temperature: - 30 ~ + 70℃

2) Dim size:φ25 ~ 35 mm

3) Medium pressure: < 1.6 MPa

4) Pulverized coal concentration: 0 ~ 40 Kg (solid)/Kg (gas)

5) Medium speed: 7 ~ 25 m/s

6) Measuring range: 0 ~ 10 t/h

7) Accuracy: plus or minus 3%

8) Power supply: AC220V / 1 kva

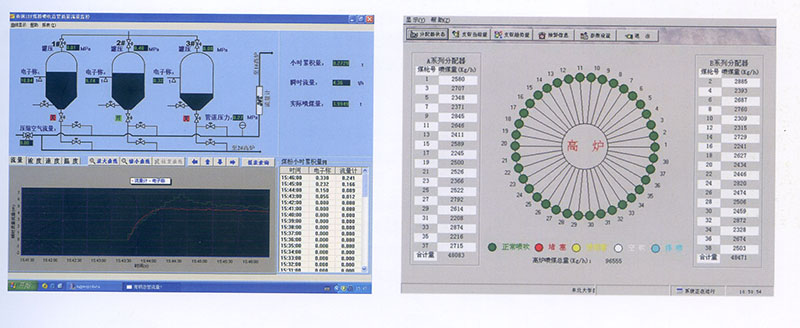

Typical configuration and interface