Status quo

The biggest problem of power plant boiler wind speed air flow measurement is that the measuring device is easy to block, easy to wear, uncertainty, installation inconvenience.

Boiler wind speed is hard to realize online accurate measuring, so the boiler combustion adjustment real-time optimization can’t be realized.

Solution

DLT_W8000 series wind speed on-line monitoring system is a successful solution to the above problem. It is tested fieldly hundreds of times, long-term for the most advanced research results of gas-solid two phase flow.

Characteristics

1) Anti-blocking. Using leakage blocking design and self-cleaning gray patent technology,it makes the devices do not need to purge,can be used for a long time, running in gas-solid two phase flow long-term reliable operation, without using additional measures, long-term maintenance free operation.

2) Antiabrasion. The pressure probe fired with special ceramic and alloy to make by the wear deformation,it can effectively prevent the probe to ensure high accuracy of measurement. Temperature measuring device shell also uses special wear materials, which be used in the wind powder duct (mixture of coal, coal mill export and fluidized bed measuring wind), life can reach more than five years.

3) Small pressure loss. Installing the measuring equipment in the wind pipe will not affect the original wind speed; In large air duct, the energy consumption of the motor can reduce for the small pressure loss.

4) High precision. Cold calibration and hot temperature compensation technology effectively improves the accuracy of measurement. multi-point matrix measuring probe is used in general secondary wind, big mill inlet air duct, ,which guarantee the high precision measurement under the condition of short straight pipe and the flow field in turbulent flow.

5) Easy installation. It does not affect the original equipment structure, installing time is short, and workload is small.

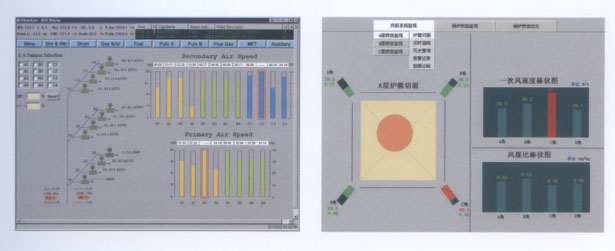

Main function

1) Monitoring the first wind speed and air volume of every burner (including the storage type hot air conveying powder, reservoir type exhaust in powder, direct blowing pulverizing system).

2) Monitoring the second wind speed and air volume of every burner (including on the air duct, direct blowing type coal mill inlet airflow measurement).

3) Fault diagnosis, such as: fault diagnosis, lack of coal powder, blocking pipe diagnosis, etc.

4) Show wind speed, air volume, fast and help operators exact judge working condition of a secondary air.

5) It can be used for boiler combustion adjustment and performance test.

Performance indicators

1) Accuracy: plus or minus 1%

2) Prevent abrasion: keep 2 overhaul period does not need to maintain.

3) Signal output: 4 ~ 20 ma, differential pressure and wind speed signal is optional.

Typical configuration and interface

National patent no. : 200920255630.8