The production and management of the electric power enterprise generally divided into three levels, operational level in the bottom, the production management in the middle, management of business in the top., In our country ,many power plants are established are running operator based on DCS/PLC of the modernization of the main auxiliary control system at present, the level has reached or close to the developed countries in the world. Operation and management of MIS which has been builded up, works in the service of transaction management, such as asset management, office automation, human resources, financial management, etc., The main reasons for economic indicators is not high of our countryis that intermediate missing for production and technology management automation network. China national electric power company in 2015 in the science and technology development plan clearly put forward, large and old plant must bulid plant-level monitoring information system (SIS), and would make it perfect and popularization and application, required the power plant must put the safety of electric power production and economy, pay equal attention to optimize the production process, reduce the production cost and equipment loss, improve the level of power plant of modern management, to adapt to the needs of the development of power market.

Solution

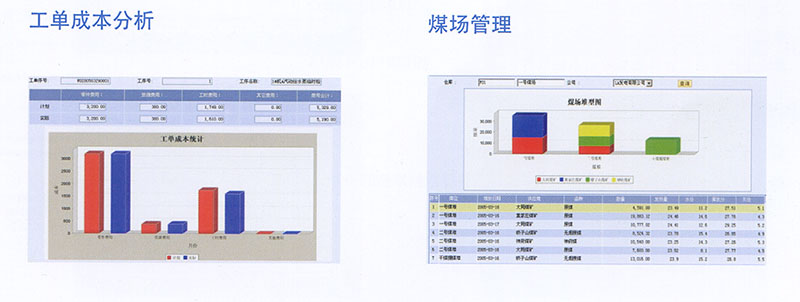

Delto DLT - SIS8000 Supervisory Information System is automation management software geared to production and management, it is the realization in individual control system in the factory and factory production process optimal control and management system, is also core to contact each production process of enterprise internal control system and management information system.

System composition

Real-time data colltction-- -- -- -- -- - provide the production information sources for system

Real-time/historical database -- -- -- -- -- - the core of the system

Function of application software -- -- -- -- -- - the key to the successful application of the system

Function

1) Real-time information display for production

2) Calculation and economy analysis

3) On-line monitoring and analysis

4) Prediction and preventive maintenance

5) Load optimal operation

Characteristics

1) Power plant energy analysis method

2) Basic value modificate on-line

3) Rich I/O drivers

4) Complete OPC structure

5) Simple and quick ability of second development

6) Seamless integration with third party systems

7) Developmental and expansibility of the system

8) Good extensibility.

Design principles

1) Connection of all the bulding with fiber optic of 1000 Mbps Ethernet.

2) Connection between floor and the control system with fiber optic of 100 Mbps Ethernet.

3) Connection between each control room with fiber optic of 10/100 Mbps Ethernet.

4) Multilayer distributed structure;